Software Defined Radio ( SDR ) . . . defined

At the PTC Congress last week in Miami, a Union Pacific (UP) panelist was asked about the real estate on top of the locomotive as to the placement of antennas in the light of the 220 MHz band that is to be used for PTC. The UP manager stated that, in fact, there can be up to 14 antennae mounted on a locomotive, and Yes! they are getting crowded. The number was quite a surprise for me in that my quick count could only come up with 10 (which is a pathetic number in itself), i.e., GEO satellite, 40MHz, 160 MHz-voice, 160 MHz-data, 450 MHz, 900 MHz, cellular, WiFi, GPS, and 220 MHz. Now, moving into the cab, the large number of antennae implies that there is a significant number of radio units mounted in nooks and crannies, with each unit most likely servicing singular applications with singular protocols via singular frequencies, e.g., voice, end-of-train (EOT), locomotive diagnostics, event recorder download, and distributed power.

Ah Yes! I can’t help but think back just 20 years ago when railroad communications engineering was so straightforward. At that time, wireless on the locomotive was limited to voice radio with the introduction of EOT as the first major use of radio telemetry across the industry. Granted, railroads were even less efficient than they are today, but there was plenty of excess of everything, so what the heck? We didn’t need wireless data to advance resource management processes. The big thrust then was the transition from crystals to the use of synthesizers to provide a full slate of channels on a single locomotive radio unit. While the railroads’ communication forces may consider their expansion of wireless data technology since then to be progressive, as suggested by the locomotive’s antenna farm, I view the transition as being totally tactical and not at all strategic. So! Is that being progressive … or is it just being evolutionary? The difference between those two perspectives is extraordinary. That is, the additional cost of being tactical instead of strategic includes an extraordinary amount of capital investment, maintenance, opportunities to delay trains due to inoperable equipment, as well as an extraordinarily poor IT architecture (both physical and logical) due to the lack of system integration resulting in an extraordinary inhibiting of advancing railroad operations in a revolutionary fashion instead of an evolutionary one. By this last point I mean that railroads have failed to use wireless technologies to advance the management of their key resources from that of being reactive to that of being proactive, as discussed in other postings on this blog.

Unfortunately, the technicians have been free to do what they like to do most, i.e., design communication solutions that are tailored to specific applications. If they were asked to justify why they didn’t consider pooling applications on a single radio, for example, they would have a number of seemingly good technical reasons, of which some would have some merit. However, the bottom line is that they have not been required to build a multi-function or multi-band wireless platform that would reduce many if not all of those extraordinary items mentioned above. This is where software define radio (SDR) comes into play.

With the term SDR being introduced as recently as 1991, it can most simply be described as replacing a number of hardware components of a radio unit with software. The underlying principle for doing so is the use of some form of digital signaling processers (DSPs) that can replace specifically designed hardware such as RF filters, mixers, amplifiers, and modulators/demodulators. While that sounds interesting, the truly great point is that a single signal processing platform can service an unlimited number of combinations of bands and protocols. It only needs the appropriate software; software which can be accessed instantaneously to provide a different radio platform to the same user.

The real breakthrough in SDR began with the rapid, exponential increase in the power of general purpose processors to service the PC market. Again, simply stated, that meant that a standard computer and the corresponding advancements in software programming could advance SDR much more rapidly than continuing to rely on the much slower advancement in specialized DSP technology. What better example of this is there than the iphone and its competitors that can handle multiple protocols, e.g., 3G, 4G, in a fashion transparent to the user?

It was a decade ago that I reached out to several companies that were then beginning to use the general purpose processors found in PCs instead of specialized DSP to deliver SDR to the military – industry complex. One such company accepted an invitation to present their concepts, using a laptop computer, to the AAR’s wireless committee. They came, they saw, and they retreated. The interest by the railroads’ technicians was one of moderate curiosity without any incentive to do anything different than what they were then doing to avoid the inevitability of meeting the FCC’s narrow-banding push of the railroads’ 160-161 MHz band. That was then, What about now? Interestingly, the answer is that the technicians have totally swung to the other extreme of the pendulum. That is, instead of spinning wheels to achieve nothing, they are totally involved in creating the ultimate wireless data network and thereby ignoring all other possibilities as to advancing technologies as well as alternative approaches to spectrum usage.

SDR is only one possibility for advancing the cost-effective and efficient use of wireless across the rail industry that will be discussed in future posts on this blog. For example, I will be addressing soon the software defined antennae (SDA), that in sync with SDR, provides the basis for cognitive radio.

Benchmarking Wireless

So many words, phrases, and processes that were used in 70s regarding computers have faded to the point that it is likely that few under 50 years of age would have heard of them, yet alone understand their usage. I am referring to terms such as core memory, thrashing, I/O bound, DP, TOS, DOS, boot strap, JCL, punched cards, re-IPLing, LCS, and core dump. This was the era of mainframe computers with orders-of-magnitude less processing power and storage than available today at orders-of-magnitude higher prices. Indeed, as the phrase DP suggested, this was a period of batch processing of data, e.g., payroll or inventory update, versus that of dynamic generation of information.

So many words, phrases, and processes that were used in 70s regarding computers have faded to the point that it is likely that few under 50 years of age would have heard of them, yet alone understand their usage. I am referring to terms such as core memory, thrashing, I/O bound, DP, TOS, DOS, boot strap, JCL, punched cards, re-IPLing, LCS, and core dump. This was the era of mainframe computers with orders-of-magnitude less processing power and storage than available today at orders-of-magnitude higher prices. Indeed, as the phrase DP suggested, this was a period of batch processing of data, e.g., payroll or inventory update, versus that of dynamic generation of information.

Back then, one process in particular was extremely important when making decisions about the investment in computer systems. That is, customers would often require that a computer supplier to benchmark it’s various levels of systems, or against competitor systems, to compare the efficiency and adequacy relative to the cost of those systems. In truth, having been actively involved in such activities as an IBM DP Marketing Representative, benchmarking was more often than not a shell game played by the vendors’ System Engineers that tweaked each part of their computer parameters (constraints such as I/O speed, partition size, disk access speed, etc.) to maximize the throughput of a particular a system in favor of each customer’s individual expectations. Getting the customer’s order was often the result of the vendor’s Marketing Representatives and System Engineers working together to set up the customer expectations and then to demonstrate the ability to meet them, respectively, euphemistically referred to as having account control.

With the move from back-office / mainframe computing to that of distributed client/server, the art and science of benchmarking has become that of legends for those still able to remember the good ole days. With seemingly unlimited computer power and communication links, there is rarely an issue today of whether or not the IT architecture will handle the requirements and at what cost. Over the last several decades the investment decision has shifted from costs/power to that of developing / obtaining the software relative to business value. Well, that’s almost totally true. For industries that rely on substantial mobile and remote resources, advancing IT can also be a significant infrastructure and hardware cost as well and therefore worthy of benchmarking. Unfortunately, that continues to NOT be the case for railroads.

As I have noted in other postings on this blog, and in my quarterly publication, Full Spectrum, most of the major railroads in North America have failed to develop a strategic technology plan in sync with a strategic operations plan (Strategic Railroading™). What is not understood, and therefore not appreciated or evaluated by railroads, is the paradigm shift that can be made for these predominantly unscheduled railroads by increasing the accuracy and timeliness of the status of their key assets, including track time, locomotive diagnostics, fuel, crews, and yard occupancy. And, the primary technology to do that is wireless data. So, if companies found it appropriate to benchmark computer systems for the paradigm shift that they made in the 70s by replacing clerks with MIPS, then why are the railroads not doing the same in pursuing their deployment of wireless? There are two points to consider to address this question, i.e., MOTIVATION and PROCESS.

MOTIVATION

In the case of railroads with 1000s of locomotives and the possibility of incorporating them as mobile nodes on the IT architecture, as a manufacturer would consider fixed nodes, then there is definitely something missing. What is missing is the understanding by railroad management, and suppliers failing to taking a proactive position, of what can be done with IN-TIME data. I am not referring to REAL-time data. The difference between IN-TIME and REAL time is critical in understanding the constraints of using wireless data, versus the seemingly infinite capability of wired links as in a manufacturing environment. To be explained in a future posting, IN-TIME data for train speed and position information in unscheduled operations is no more frequent than every 5 minutes for other than moving block operations. Hence, the railroad technicians that are charged with designing wireless networks can’t help themselves, nor are they held responsible, in making technical decisions which are not related to true business evaluation. Stated simply, technicians will always over design to make sure that they don’t come up short.

PROCESS

As nearly everyone now appreciates with the proliferation of cell phones and laptop computing, wireless is clearly limited in its throughput speed and coverage. It has been an eye-opening experience for those folks that expected that their internet connectively on their cell phone and notebook would match their in-the-office-cubicle desktop performance. There are two primary ways to determine what needs to be done.

1. evaluate every possible wireless-based application as to data requirements and calculate the ultimate throughput requirements. At least one railroad tried this approach several years ago, and the process bogged down in detail thereby insuring nothing would be resolved.

2. evaluate on an 80/20 basis as to evaluating throughput requirements relative to a variety of wireless options recognizing the two key parameters of wireless data parameters. i.e. throughput and coverage. This approach was used a decade ago when I structured such a study that was participated in by the big 4 railroads in the U.S. with oversight by the AAR. The results of that study were used at that point by the AAR to justify the industry’s usage of the 160 VHF spectrum to the FAA. However, that was all the farther it went. Basic details follow.

Developing a Wireless Strategy for a railroad, or for an industry, needs to be pragmatic and adjustable to each railroad’s technical agenda, assuming there is one.

The process is rather simplistic in structure, but a true commitment is required by a railroad’s upper management to provide the players involved with the proper motivation to address the bottom line at the same time. To be brief, the process requires developing a matrix that plays off THROUGHPUT requirements against COVERAGE. For railroads, the THROUGHPUT requirements may include simple categories such as Voice, Monitoring (locomotive diagnostics, shipment status), Out-bound Transactions (PTC targets), Process Control (moving block), and Interactive (M of W activities, in-train management). As to COVERAGE, the categories can be as simple as Terminal, Metropolitan (major cities with multiple railroads), Main Line, and Group (M of W gangs, Trains/Cars). Within each Throughput / Coverage block of the matrix, the possible applications are identified with a pragmatic evaluation of data requirements. This provides the Demand perspective.

The next step is to evaluate the various wireless data options, both commercial and private, as to their ability to service the demand. This is the Supply perspective that results in Wireless Corridors, if you will, that permits structuring a manageable number of wireless strategies based upon business evaluation as to costs vs. value. Such an analysis, in my belief, would have prevented the phenomenal, unwarranted investment in the 220 MHz spectrum that is being made in the name of PTC, even though the railroads are required to spend $100s millions to rebuild the 160 MHz infrastructure as required by the FCC by 2013.

For those small to medium railroads outside of North America that are being slammed with ETCS, and the requirement for GSM, the analysis goes even deeper. That is, as described in other postings on this blog, the use of dark territory (with or without PTC) and the deployment of cost-effective wireless solutions can provide substantially lower capital investments to run a railroad both safely and efficiently.

Bottom Line, railroads should be benchmarking the use of wireless technologies with a pragmatic understanding of both Demand and Supply. Further details of such a process can be obtained by contacting me to discuss individual situations. This is what I provide as a consultant.

PTC: Caveat Emptor

Prior to the PTC mandate in November 2008, the misunderstandings about PTC were starting to narrow down to just a few issues. Fortunately, the fact that PTC is not vital had fairly well stabilized across the industry. But there remained the most persistent, fatuous belief that PTC delivered business value, followed closely by the corollary that such business benefits would be achieved after the deployment of PTC. Actually, the second point is pathetically true somewhat because there is a tremendous lack of understanding, proper management direction, and executive bonus incentives as to what railroads can do NOW without PTC with the use of the simplest of wireless data infrastructures, whether it be owned and/or commercial (cellular / satellite). As proof of this point, as noted in previous postings on this blog (Really! You Gotta Let It Go), NS is leading the charge in the industry, followed by BNSF in actually achieving such business benefits now without PTC.

Since the mandate of PTC, a whole new plateau of misunderstandings and misrepresentations regarding PTC has been reached. Some of these are perhaps innocent mistakes, but others are clearly the result of misleading, if not fraudulent, activities by suppliers and consulting firms alike. This is not a point of concern for the Class Is in that they know what PTC is and what it will take. Afterall, they have taken the charge to define PTC themselves with little to no interest in help from the supplier community. My concern, rather, is for the commuters and regional rail transit systems that are looking for a path through the PTC implementation mine field armed with regulations, budget constraints, the challenge of public financing, and long-established relationships with selected suppliers who have no experience in PTC.

PTC, as to be deployed in the U.S, is only one form of enforcement systems that are meant to ensure that movement authorities are not violated as to some combination of time, distance, and speed. They are deployed to prevent train crew errors (whereas traffic control systems prevent dispatcher errors). Examples of enforcement systems in addition to PTC include, Advanced Civil Speed Enforcement System (ACSES) as used by Amtrak on the NE Corridor, various forms of Automatic Train Protection (ATP) as deployed across Europe and elsewhere (e.g., ETCS, LZB ), and various forms of Automatic Train Control (ATC) over the years. The critical point here is that while all of these systems are enforcement systems, they can differ substantially as to the technologies and challenges involved in designing, implementing and maintaining. Consider the following differences between PTC and ACSES.

APPLICATION

ACSES is an overlay on cab signaling for the NE corridor. Contrarily, PTC is an overlay system for traffic control systems other than cab signaling, including both dark (non-signaled) and signaled operations.

FUNCTIONALITY

ACSES, as originally designed, does not provide for 1 of the 4 core objectives of PTC as mandated. That is, it doesn’t provide protection for work gangs in the NEC in that those workers do not have authorities, per se’, to be there. The maintainers use watchmen to inform them of approaching trains. (BTW, I have a patent pending for a slick solution to this problem. But getting funding, yet alone purchase orders, has been impossible.) ACSESS II will provide for such protection I understand. Additionally, neither PTC nor ACSES have addressed the likelihood that additional capabilities will be required by commuter and regional rail operators – more on this in a forthcoming posting. Lastly, the critical aspects of the braking algorithm for freight trains, compared to the relative simplicity of passenger trains, will be an on-going challenge as to the reliability and acceptance of PTC.

ARCHITECTURE

PTC is dependent upon a ubiquitous wireless data network with a different set of wayside / in-track components than that of ACSES. Also, PTC requires a central-office server that links with the dispatching and signaling platforms through various means. PTC requires its own on-board platform that will most likely be integrated at some point with other on-board systems for advanced train / locomotive management.

MAINTENANCE

Given the substantial difference in architecture and functionality between ACSES and PTC, it is not difficult to understand that the maintenance issues are substantially different.

TRAINING

Given the substantial difference in architecture and functionality between ACSES and PTC, it is not difficult to understand that the training issues are substantially different.

INSTALLATION

Given the substantial difference in architecture and functionality between ACSES and PTC, it is not difficult to understand that the installation issues are substantially different.

MANAGEMENT

I know nothing of the type of management overview that is used by Amtrak’s operations management regarding attempted violations, etc. of ACSES operations, but providing the same for PTC will be more complex . . . that is once the railroads recognize that this is a requirement.

Considering the above, I come back to the point of misunderstanding / misrepresentation by suppliers and consultants following the mandate of PTC. First, I provide the They’re Just Stupid perspective followed by the They’re Lying perspective of what is happening in North America to the likely disadvantage of both the commuter / regional rail operators as well as the suppliers / consultants with legitimate PTC credentials.

They’re Just Stupid

Yes! ACSES / ATP / ATC / ETCS, etc. do provide for various combinations of PTC functionality as mandated. However, having designed, implemented, and/or consulted on ACSES, ATP, ATC, ETCS, etc. does not qualify a supplier or consultant in any fashion to say that they have PTC experience given the above comparison between PTC and ACSES. But yet, consulting firms and suppliers that had not been involved with PTC development in any fashion prior to the mandate have since expanded their credentials and list of brochures presenting themselves as PTC experienced. To do so is an act of stupidity and/or blind arrogance on their part. BTW, CBTC credentials are not appropriate either.

They’re Lying

Yes! ACSES / ATP / ATC / ETCS,etc. do provide for various combinations of PTC functionality as mandated. However, having designed, implemented, and/or consulted on ACSES, ATP, ATC, ETCS, etc. does not qualify a supplier or consultant in any fashion to say that they have PTC experience given the above comparison between PTC and ACSES. But yet, consulting firms and suppliers that had not been involved with PTC development in any fashion prior to the mandate are scamming clients that they have such expertise with a hope and a prayer that they will get the contracts and learn on the job or hire the necessary truly qualified talent. BTW, CBTC credentials are not appropriate either.

In closing, a RFP was issued by the FTA to study the issues of deploying PTC across commuter and regional rail operators. That RFP has now closed as to the submission of proposals. It will be interesting to see what team is awarded that contract as to their actual vs. promoted credentials; definitely a forthcoming posting.

Wilde about Railroads

“The way of paradoxes is the way of truth”

“To test reality, we must see it on the tight-rope. When the Verities become acrobats, we can judge them.”

With these two statements the reader is soon introduced to the underlying principle of paradox throughout Oscar Wilde’s only novel, The Picture of Dorian Gray. This piece of literature drips with often-veiled aphorisms that either challenge or enlighten one’s intuition of humanity and society. While the author’s nearly-religious pursuit of beauty was the motivation behind this writing, the truisms revealed have applicability today … and, if you will grant me some wide-ranging poetic freedom, within the rail industry. Consider the following quotes and their applicability to railroads; the OSCARS if you will.

“I can stand brute force, but brute reason is quite unbearable. There is something about its use. It is hitting below the intellect.” . . . Operations management if pressured to run to schedule.

“The true mystery of the world is the visible … not the invisible.” . . . Operations management if pressured to recognize and integrate yard status in managing the main line lineup.

“Punctionality is the thief of time.” . . . Advocates for running a truly-scheduled railroad.

“People know the price of everything and the value of nothing.” . . . Why the railroads need technologists (and not technicians) to pursue NOW the transition of analog VHF to digital VHF.

“Faithfulness is to the emotional life what consistency is to the life of the intellect – simply a confession of failure.” . . . An evaluation of those who refuse to break with traditional methods of operations even though there are substantial benefits to be had.

“Good artists exist simply in what they make, and consequently are perfectly uninteresting in what they are … inferior poets are absolutely fascinating.” . . . The boredom of running a scheduled (but efficient) operation vs. the “excitement” of traditional crisis-based railroad management.

“To be good is to be in harmony with one’s self … discord is to be forced to be in harmony with others “ . . . Why non-scheduled operations causes strife within a railroad.

Traffic Movement: Safety vs. Management

Recently on this blog I posted the article Dangerous Railroading in which I identified 4 primary areas that a railroad needs to address for safe operations, i.e., 1. choice of safety systems deployed, 2. critical infrastructure maintenance practices, 3, personal / personnel accountability, and 4. theft of critical infrastructure. The primary point of that posting was that a railroad’s slack in any one of the four areas would result in the safety of its operations being readily compromised. In that posting I addressed each of the areas in a cursory fashion with the commitment that I would address each in greater detail in subsequent postings. As such, this posting addresses safety systems with additional discussion as to Traffic Management.

There are two levels of safety systems to consider for the movement of trains from both the dispatching and train crew’s perspectives, i.e.. traffic control and enforcement, respectively.

TRAFFIC CONTROL

Simply stated, traffic control is the functional vitality of the railroad that ensures the integrity of train movement authorities. It does that by employing vital logic / hardware / systems that generate the movement authorities in a fashion that fails safely, i.e, unsafe authorities are not delivered. I am purposely pointing out the difference between functional vitality and logic / hardware / system vitality here in that the distinction is often overlooked, if even recognized by many railroaders. Logic / hardware / system vitality is that which signal engineers solely identify with. Too often, signal engineers mistakenly believe that signals are installed for safety purposes. Of course, signals provide for safety, but they are installed for traffic throughput in that it is possible to operate a railroad safely without signals, e.g., 50% of the trackage in the US is non-signaled traffic control. … as is ETCS level 3, … as is the most primitive token block system. Signal engineers don’t identify with functional vitality, a point which is quickly proven by asking ANY signal who has not taken my Railroad Immersion Course (brochure is available on the blog), “What’s vital in non-signaled (dark) operations?” Their response will always be “Nothing!” since there is no hardware installed along the wayside. They are so, so wrong from a functional standpoint. Vital functionality is what a railroad requires, and the vital logic / hardware of signaling systems is only one way to achieve that. (Further discussion on this point, as well as the answer as to what is vital in dark territory, is provided in a previous posting on this blog in the Teddy Bears category: There’s Nothing Vital in Dark Territory).

Arguably, the most disturbing issue currently about traffic control is the willingness by too many railroads to blindly accept both the traditional and advanced traffic control systems that are offered to them by traditional suppliers pushing what they have, versus what those railroads really require. I am not referring to high speed, high capacity operations as in Europe’s passenger operations where interoperability and traffic density are the driving factors. Rather, I am referring to all of those railroads across the other 90% of the globe that are struggling to develop a core transportation infrastructure to expand their country’s economy. How dare traditional signaling companies and consulting firms provide only products that feed the seller’s bottom line instead of pragmatic cost-effective solutions that service a railroad’s bottom line. These suppliers are providing, as well as the consultants are promoting, products instead of true solutions. (Again, I refer you to another posting on this blog: In the Light of Dark in the Railroad Business category.)

ENFORCEMENT

Unlike traffic control which is meant to prevent dispatching errors, enforcement is meant to prevent train crew errors. Simply stated, enforcement systems monitor the status of a train’s movement relative to its authorites. Should the system determine that the train is in jeopardy of violating an authority as to some combination of speed, distance, and time, then the enforcement system takes some combination of actions such as warnings to the crew, slowing the train, or bringing the train to a complete stop. As such, enforcement functionality can be integrated with advanced traffic control systems such as ETCS in Europe, or it can provided as an overlay system, as is the case with PTC in North America. In any event, enforcement systems are not vital as to functionality or logic / hardware (as discussed above) in that they do not generate authorities. Should, the enforcement system fail in some fashion, then the train is no less safe than it was without the enforcement system . . . Well! Almost always. One possible exception is that of an improperly designed enforcement system that makes an emergency brake application that for some reason results in a derailment.

Various types of enforcement systems have been in use in passenger operations for decades. However, for freight operations across most of the globe, enforcement systems have been extremely limited in their deployment and functionality compared to what is now available with PTC and the European flavor of Automatic Train Protection (ATP) as well as enforcement functionality incorporated in ETCS for Europe’s High Speed Passenger operations. What is unique about PTC relative to ATP / ETCS, is that no significant additional wayside infrastructure (other than a commercial or private wireless data network) is required for a very basic approach in signaled territory, with only switch monitors required in non-signaled operations. NOTE: For the hardcore PTC followers who feel tempted to correct me regarding WIU’s being required in signaled territory, I request that you first think about why WIU’s are needed if interim signals are not enforced.

TRAFFIC MANAGEMENT

Neither traffic control nor enforcement is traffic management. Traffic management deals with the efficient generation of authorities, but not the generation itself. It is designed to meet the operating directives (business value) of the railroad in managing the key resources, and as such has nothing to do with the safety of the railroad. Until recently, traffic management has been dependent upon the analytical and the rationalization of a railroad’s management team as to what was most important, i.e, moving high priority trains regardless of the cost associated with other traffic. It has only been within the last decade that advanced traffic management has introduced the mathematical tools that can displace the limited human-mentality of dispatchers to deal with the most simplistic prioritization of track time only, yet alone consider fuel utilization, crew availability, balance of locomotive distribution, and the constraints of track maintenance. I should point out that I am referring primarily to non-scheduled operations that are prevalent in North America. I am not referring to high speed passenger operations that are highly scheduled. (One more time, I offer two other postings on this blog relative to traffic management, both from the Teddy Bear category: 1) CAD Delivers Traffic Management, and 2) Train Dispatching is too Difficult for that Math Stuff.

Hey! Watch this.

Last week there was the story on National Public Radio about the young fellow who challenged his friends to the old chestnut about not licking a stop sign’s metal pole in freezing weather. The story went on to state how the boy was standing on the tips of his toes for 15 minutes until the firemen were able to release his tongue.

Hey! Watch this! (H!WT) Ah yes! The last spoken (and printable) words of impetuous young males who fatuously attempt to perform ridiculous if not impossible acts. Whether it is a passion for the limelight, a flash of perceived brilliance, or a display of bravado, whatever, such acts of pure stupidity can result in serious degradation of the soul, if not destruction of the body. Fortunately, somewhere in our post-teen years we mature and we take on a sense of self-preservation for the benefit of ourselves and our family and learn to not yield to such temptations. We become responsible and reflective and make clear cut, well-justified analyses of the matters at hand before we take action. And, should we find that we are in error with the actions we took, then we adjust our reasoning by adding a new variable to the equation, or perhaps adjusting the coefficients, and we are then just that more effective should the situation occur in the future. Yes! Life is good … and all makes sense . . . eventually. Well! Maybe not always.

Unfortunately, stuff happens that is forced upon us, instead of being of our choice, and the manner in which we respond is more often than not, I believe, directly related to the level of the chaos of the situation. That is, the more chaotic / disturbing the situation, the more ill-structured, the more irresponsible our reaction may be. In such situations, the impulsive H!WT response still occurs but in a reactive fashion versus the proactive fashion of our youth. Now, if you mix this reactive response with politics and a high level of public exposure, then you have the underlying explanation of why Positive Train Control (PTC) has been mandated in the U.S. This is a situation where a proactive H!WT begot a passive H!WT. First, some statistics.

According to the U.S.’s General Accounting Office (GOA) report of December, 2010 regarding Rail Safety, Human errors have been the primary cause of rail accidents (34%) for the past decade relative to 5 other common causes. Track issues are a close second (32%), with the remaining 1/3 due to crossings, equipments, signals (only 2%), and the ever present other. As to the movement of trains, the two primary human factors are dispatchers and train crews. While traffic control systems are used to prevent dispatcher errors, there has been very little provided prior to PTC to prevent crew errors across North America’s freight railroads. Back to H!WT.

The train accident at Chatsworth, CA on September 12, 2008 between Metrolink and UP in which 25 people died was a proactive H!WT on the part of the Metrolink driver that thought he could text message while operating his train. In less than 5 weeks Congress did their H!WT knee-jerk reaction, as in we have to stop the carnage due to train crew errors, by passing the Rail Safety Improvement Act of 2008. This act mandates PTC before 2016 across most of the nation’s trackage. Clearly, there was no cost vs. value justification, even though it was already known by the FRA and the railroads from the RSAC-PTC process that PTC was not cost justified on safety benefits. From Congress’s standpoint, something just had to be done, regardless of the cost. And, about those costs, the price tag is horrific. Specifically, as estimated by the FRA, the cost of meeting the mandate ranges from $9. Billion to $13.1 billion. As to the benefits, the safety value of PTC over 20 years is estimated to range between $440 million to $674 million. That is a 20-to-1 cost/value ratio that is way beyond any rational business decision that would be made in the private sector. Undoubtedly, to their defense, Congress was being fed misleading statements of PTC delivering business benefits (see my previous posting Really! You Gotta Let it Go), Additionally, NTSB was stoking the PTC fire with its long standing proclamation that PTC was on its Most Wanted list. Rational financial thinking was out of the window, and self-preserving politics were in play for those on the Hill.

Although the Chatsworth tragedy was directly responsible for the mandating of PTC, it was not the first to tempt such fate. In 1996, a MARC commuter collided with Amtrak in Silver Springs, MD resulting in 11 deaths. Given that its engineer was the driver of the MARC commuter and was at fault, CSX decided to pursue the development of the yet-to-be defined overlay PTC concept. CSX did this in anticipation of a H!WT by Congress, especially considering that the accident took place in Congress’s backyard. This is where I entered the picture in that I was hired by CSX at that time to deliver what was then referred to as Positive Train Separation (PTS). The resulting system, known as Communications Based Train Management (CBTM), provided the underlying architecture and functionality of the current PTC pursuits by the freight railroads to meet the mandate.

So! Why did Congress not do a H!WT after the Silver Springs’ accident? The answer, I believe, is two-fold. First, UP was in the process of abandoning an extremely expensive and undeliverable Precision Train Control (PTC™) system. Although the same acronym as Positive Train Control, there is a key difference between PTC™ and PTC. That is, PTC™ was meant to be both a traffic control (moving block) and enforcement system, whereas PTC is only the latter. Undoubtedly, UP and its Class I siblings had to be all over the Hill at that time to prevent a mandate of such a technology. The second reason is that CSX took the initiative to “develop something that is effective, but cheap” as were my marching orders, thereby lessening of the pressure on Congress to H!WT .

There was also a second accident that could have resulted in the mandate of PTC. In January 2005, a NS train proceeded through a misaligned switch and collided with a standing NS train in Graniteville, SC. This accident involved hazardous material and resulted in 9 deaths and the evacuation of 5400 residents within a mile of accident for 2 weeks. While it didn’t result in a mandate, the accident did result in a fourth core objective of PTC, i.e., prevent movement through a misaligned switch, in addition to the original 3 core objectives defined in the RSAC-PTC process nearly a decade earlier: 1. prevent train-to-train accidents (PTS), 2. prevent over-speeding, and 3. prevent trains from endangering on-track workers.

PTC is definitely not justified on safety benefits, and it doesn’t deliver business benefits. At first that seems bad for PTC deployment outside of the U.S. However, that is really not true in that there are so many railroads, whether private or state owned, that don’t incorporate safety as part of the mantra of operations. There are so many railroads, whether private or state owned, that are being forced by traditional suppliers with traditional solutions to deploy traffic control and enforcement systems that are totally unjustified for their level of operations. In these environments, the consideration of PTC in concert with non-signaled traffic control, a.k.a. dark territory, would present a solid, cost-effective solution for both safe and efficient operations – that is if they were willing to listen. Now, as to North America, PTC is really not a loser financially as well, that is if there would be a strategic technology plan associated with its implementation that permits the necessary wireless data platform to be used for business benefits as well. Unfortunately, however, most of the Class I’s have not gained such a perspective. This is due to the fact that there are so few technical staffs of the railroads, and even less executive management teams of railroads and suppliers alike, that are willing to do a proactive H!WT as to syncing a strategic technology plan with a strategic operations plan. Yes! I am referring to Strategic Railroading™.

In closing, I will be the Chairman of the PTC Congress in Miami, FL on February 22. If you and/or your colleagues are attending that event, then I would appreciate the opportunity to meet you.

Significant Digits

Railroad execution and planning need to be dealing with the same range of significant digits.

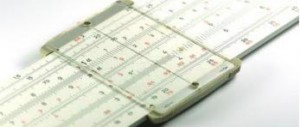

For those of us who began our engineering studies before the 70’s, the practicality of the slide rule is well appreciated. This intriguing device of sliding scales, that miraculously performs multiplication and division via the addition and subtraction of non-proportional linear distances, minimized the terror of dealing with an endless flow of variables encompassed in complex engineering equations. That was the heyday for analog mathematical devices as digital computers were being somewhat reluctantly infused into the engineering ranks, and accordingly, it was the pinnacle for the art of approximation, the art of defining squishy limits. Using the slide rule required thinking in terms of powers of 10 as well as understanding that there was a clear rationale to acceptable precision, what was referred to as “significant digits”. For example, did the resulting answer of 8.something shown on the slide rule’s “D” scale after multiplying and dividing a series of 27 numbers actually mean 8.2 ? or 8.25 ? or perhaps was it .0082 ? or maybe 8200 something? Back then, “being close” was good enough, in fact expected, as test scores were partially determined by the proper use of the slide rule.

With the introduction of the personal calculator, arrived the immediate requirement for precision. This was not a level of precision, however, that one had to work for, but instead it was that which was instantly provided to the user on green-lighted displays. If one required the square root, or even a discounted cash flow, one needed only to push the appropriate function key once the data had been entered. And, there was no limit to the number of digits of preciseness it seems. The mind was given the answer, without thought, without question and, unfortunately, without the opportunity to truly understand the underlying mathematics.

Interestingly, for major railroads in North America and across the globe that are either primarily non-scheduled or without moving block operations, the planning and execution processes for traffic management employ opposite extremes of understanding the underlying mathematics and the discipline of approximation. Practically speaking, there is a very real opportunity for railroads to transition train dispatching from an art to a science by including mathematics-based movement planners. Currently, the approximations inherent to moving trains are so broad that the railroads are running below capacity in critical corridors. These inefficiencies are due to the lack of both timely train position and speed and the tools to handle the continuous mathematical processes, specifically reactive and proactive planners. The former would assist the dispatchers with the current approach of crisis-based traffic management, whereas the latter would provide for the prediction of traffic conflicts and subsequently the ability to avoid them.

Whereas the execution side skimps on the mathematical processes, thereby resulting in broad approximations, the planning side of operations embraces the other extreme. Supported by incredibly complex mathematical algorithms being endlessly massaged on digital wizards capable of truly mind-boggling computations per second, the railroad planners pursue the absolute opposite of approximation with the concept of significant digits being totally unknown in their profession. To them, precision is a truly achievable dimension that is to be expected and respected. As such, the Planners proudly serve up their precise results to the execution side, only for many of those results to be dismissed either directly or during execution as reality sets in. This rejection is the inevitable result of either the inability or unwillingness of Operations to handle the significant problems and changes that come with execution and that inevitably make the Planners “precise” schedule an impossible reality. Operations, of course, accepts this lot in life and their thus “un-planned” execution as…inevitable, since they rationalize the events that befall the schedules to be beyond their control. However though, most are actually within their control.

The execution side has a long way to go in tightening their processes. They need the data and tools that will permit them to approach the level of performance that the planners are attempting to achieve. Conversely, the planners need to back off. They need to incorporate squishy limits into their planning processes. I have seen some asset planning tools that have managed to do that, but I assume most still do not . In a rather simplistic way, one could say that execution and planning need to be dealing with the same range of significant digits.

They clearly aren’t today.

Really! You Gotta Let It Go

In a recent issue of a rail industry periodical there was an informative article on Norlfolk Southern’s use of advancing technologies to advance their operations. What was most interesting to me was the very brief description of GE’s RailEdge Movement Planner that is being rolled out across NS’s network in concert with their next generation CAD platform. This 1-paragraph discussion validated the Proactive Traffic Management concept that I introduced 5-6 years ago in my quarterly publication, Full Spectrum, as well in Railway Age and more recently in postings on this blog.

The successful deployment of such capability has been a long time coming. Going back a decade, the GE-Harris combo first attempted to implement their moving block, Precision Train Control (PTC™), platform on Union Pacific. PTC™ (not to be confused with Positive Train Control) was abandoned eventually for 2 primary reasons. First, there was not a cost-effective wireless data solution at the time and second, the Harris side of the operation, driven by Jack Welch’s progressive positioning of technologies , had the “if we can place a man on the moon, then we can run a railroad.” attitude. They truly missed the 80/20 solution – developing solutions that will work … versus the fatuous pursuit of perfection. It seems that GE and NS have now figured it out, including the evolutionary expansion to include yards, crew operations, and locomotives into RailEdge. This is great stuff, but this is not the primary purpose of this posting.

In the same issue as the NS article there is a Guest Comment, PTC – the next great railroad revolution by a gentlemen with impeccable rail credentials. Here is an individual that has held very responsible positions across all aspects of the industry, i.e. Class I & II railroads, FRA, major supplier, and even education. But, with all of that said, this fellow just can’t give it up. He can’t give up on associating business benefits with PTC.

Below are two quotes from his commentary:

Business won’t be the same after PTC, if railroads implement it properly, business will be better – for everyone.

The continuous, accurate, real-time train location and speed information from PTC is not available to precision dispatching systems, thus making train meets and passes less efficient

In addition to the above comments, he references several FRA-supported studies that “point to the potential for substantial business benefits (from PTC).” What he doesn’t state is that he drove several if not all of those studies, and those studies were rightfully dismissed by railroads and independent consultants that could see through the primary folly. That is, PTC requires a wireless data path, as do the primary business benefits to be derived from knowing the position and speed of trains. However, a railroad doesn’t require PTC to get the wireless data network. A secondary fundamental point here is that the advancement of traffic management is dependent upon the more efficient generation and delivery of movement authorities. PTC doesn’t do either. PTC only uses the parameters of the movement authorities once they have been generated. You can read more on this subject in my previous post: “PTC Delivers Business Benefits?”

What this gentleman doesn’t understand by forcing PTC at the beginning of events to achieve business benefits is that all of the excessive PTC-design activity in the name of operability is actually holding back railroad advancement for most railroads. These railroads have failed to take a business perspective of how to use technologies now, most specifically wireless data. But, that’s not the case for NS, is it? They saw the light 2 or so years ago when it was decided to put train position/speed reporting devices on the locomotives to bring in that most simple, but most critical data that could be used by “precision dispatching systems”, to quote the commentator. And, they did it without PTC.

While I appreciate the commenter’s passion in pressing his perspective that goes back 2 decades, his lack of objectivity is a very costly, if not a financially dangerous perspective for railroads. Really! You gotta let it go.

Dangerous Railroading

Until a year ago, my professional railroading career as Class I management and an independent consultant had been almost totally dedicated to the freight industry of North America. There have been some interesting consulting engagements outside of that sphere, including a most peculiar investigation (I never knew who the true client was) into the traffic control and communication systems for railroads in the Middle East and Southeast Asia 25 years ago. But I was taken by surprise, actually shocked, when I read about the initiation of a study in that same corner of the world that would evaluate the safety and efficiency of a local railroad operation. It seems I didn’t really know what I thought I knew.

Having been nurtured for 36 years in the U.S. railroads, I had come to understand that operating a railroad safely requires disciplined allegiance to 1) safety systems, 2) maintenance practices, and 3) personal accountability. And, slack in any one of these three areas could readily result in the safety of a railroad’s operations being severely compromised. Hence, it was with the greatest dismay that I soon realized upon starting the study for the troubled railroad (hereon referred to as TRR), that it was suffering in all three areas as well as a fourth issue – the theft of critical wayside infrastructure. Given these significant problems, there have been a number of deadly train accidents across TRR, and there will continue to be unless all four areas are addressed properly. Thus, the focus of the TRR study was clearly directed to be that of safety first, and then efficiency.

The slap-across-the-face revelation for me was that TRR is NOT unique. Its dangerous railroading practices and problems are common in many parts of the world. Given the importance of railroads to emerging economies as providers of labor mobility and accelerators of industrialization – these safety and operating issues have far-reaching impacts. Thus, I have shifted the emphasis of my consulting to now focus on what railroads can do to address these 4 critical areas. In this post, I provide a brief description of each problem area as observed from my experience with TRR. Some readers will likely see similarities to their own operations . . . or their clients. Additionally, as will be addressed in subsequent postings, I will identify non-traditional, cost-effective and 100% safe solutions for each of the 4 areas. These are solutions that are not being provided by traditional suppliers that focus on the high speed passenger and/or high density freight networks across the globe. The solutions have to be non-standard / non-traditional since traditional suppliers produce and price for high speed/high density lines and these solutions can in fact result in a financial disaster for small and emerging railroads while increasing the likelihood of additional risk in their operations.

SAFETY SYSTEMS

There are two primary levels of safety systems to consider in the movement of trains, i.e., traffic control and enforcement. TRR’s traffic control is a mixture of traditional signaling (i.e., a railroad’s traffic lights) and an antiquated token block operation. While the condition of the signaled operation across TRR is understood to be below par, it is TRR’s token block operation that requires the greatest attention.

Token block originates back in the middle of the 19th Century in Britain, and its deployment across the globe was in step with the expansion of the British Empire. Simply explained, token block’s safety, as used across TRR, is based upon an operator for each section of track (block) handing a token, e.g., metal rod, to the train crew as an authority to proceed into the block. Upon exiting the block, the train crew hands back the token to the next operator and at some point receives a new token unique to the next block. In concept, token block is a safe system. But, in practice the manual processes involving the block operator and the crew can be, and have been, violated resulting in fatal accidents. For this and perhaps other reasons, various types of Radio Electronic Token Block (RETB) have replaced manual token block in Britain and elsewhere, including a relatively short corridor in TRR. But for the majority of TRR’s operation that is still manual token block, the integrity of that operation is subject to being compromised by human error. Fortunately, as to be addressed in a forthcoming posting, there are non-signaling traffic control systems that can replace token block. These are solutions that don’t require the extensive capital investment of traditional CTC operations or the overwhelming capital investment of ETCS as used for Europe’s high speed rail networks.

Traffic control safety is not the only issue associated with safe train movements. There is also the issue of train crew errors regardless of whether the operation is in signaled territory or token block, and it is the purpose of enforcement systems to prevent such errors. In TRR’s case, an antiquated enforcement approach, Automatic Train Protection (ATP), is deployed across much of the railroad. However, based upon my visits to date, it appears that the maintenance and theft of ATP components embedded in the track as well as the train drivers turning off the on-board controller so as to not be enforced for over-speeding, has rendered the system highly ineffective. To be addressed in a latter posting, ATP is quite similar in functionality to another enforcement system referred to as Positive Train Control (PTC) that is now mandated for implementation before 2016 across most of the trackage in the U.S. PTC doesn’t have the theft, maintenance, and driver abandonment problems of TRR’s ATP system.

MAINTENANCE PRACTICES

As suggested above, the adequateness and reliability of TRR’s maintenance procedures for wayside infrastructure and rolling stock are dubious. For the wayside infrastructure, TRR is confronted with an aging signaling system that is anticipated to have a major overhaul in the near future. However, much of the token block operation incorporates mechanical interlockings that, as with the token block equipment itself, are reportedly not up to grade. Such lack of maintenance is likely the result of two key issues. First, there is no regulatory process for providing mandatory maintenance procedures. Second, it is doubtful given just the physical appearance of the railroad overall, that governmental financial support has been anywhere near sufficient, if even budgeted.

As suggested above, the adequateness and reliability of TRR’s maintenance procedures for wayside infrastructure and rolling stock are dubious. For the wayside infrastructure, TRR is confronted with an aging signaling system that is anticipated to have a major overhaul in the near future. However, much of the token block operation incorporates mechanical interlockings that, as with the token block equipment itself, are reportedly not up to grade. Such lack of maintenance is likely the result of two key issues. First, there is no regulatory process for providing mandatory maintenance procedures. Second, it is doubtful given just the physical appearance of the railroad overall, that governmental financial support has been anywhere near sufficient, if even budgeted.

As to equipment, I reflect on a conversation I had with a TRR executive when I asked what he thought was the most unsafe part of his railroad. Without hesitation his answer was “The brakes.” I was then told that the goal of their operation at that time was to ensure that half of the cars (wagons) in a train’s consist were equipped with working brakes – with an additional challenge of ensuring that ½ of the brake-able cars were to be placed at the beginning and the end of each train so as to reduce in-train forces.

Outside of North America, Europe and the far East, many railroads are confronted with two critical parameters that affect their ability to perform proper traffic control and supporting infrastructure maintenance. First, there is the issue of an adequately-trained work force. However, that issue can be readily handled via the use of contractors. The second parameter is the topography over which the railroad operates, and the accessibility to the wayside as well as the availability of power. Again, solutions are available, but they can be quite expensive. The point here is that railroads subjected to such parameters should consider safety systems that minimize those requirements, i.e. minimize the amount of wayside infrastructure. However, traditional suppliers do not offer those types of systems to them – why would a supplier offer a system that has less equipment. A future posting will address this point.

PERSONAL ACCOUNTABILITY

As demonstrated by the discussion above, there is a critical lack of consistency in personal accountability across TRR in both the operations and maintenance of critical equipment. Perhaps this is due to the fact that TRR is a government-owned railroad with seemingly little incentive to address costs or revenues. Or, perhaps this is due to the lack of a regulatory body, such as the Federal Railroad Administration (FRA) in the U.S. that mandates and enforces proper procedures. Regardless of the reasons, it is clear that TRR, or any railroad, will not operate safely without a workforce totally committed to safety. To achieve that takes documented procedures, education / training, the right incentive system and discipline throughout the organization. A future posting will address these points.

THEFT

While copper wire used for pole lines has been a favorite target of thieves in the U.S. over the years, the theft of other critical components has been minimal. However, in many parts of the world, everything is fair game apparently. The treasure chest includes signaling equipment, power supplies, and in-track transponders used by Europe’s advanced traffic control system for high speed rail, ETCS. The key point here is that, as with maintenance issues noted above, a railroad should consider the vulnerability to operations and safety due to theft of critical components when selecting from alternative safety systems. The only viable solution is a system with less infrastructure to steal – but again, what supplier in their right mind would sell a system with less equipment. A future posting will address these points.

While copper wire used for pole lines has been a favorite target of thieves in the U.S. over the years, the theft of other critical components has been minimal. However, in many parts of the world, everything is fair game apparently. The treasure chest includes signaling equipment, power supplies, and in-track transponders used by Europe’s advanced traffic control system for high speed rail, ETCS. The key point here is that, as with maintenance issues noted above, a railroad should consider the vulnerability to operations and safety due to theft of critical components when selecting from alternative safety systems. The only viable solution is a system with less infrastructure to steal – but again, what supplier in their right mind would sell a system with less equipment. A future posting will address these points.

In addition to the 4 areas above, there are other significant considerations as to safe train movement operations including the use of train-integrity detection in token block operation, end-of-train monitoring of brake line pressure, wayside defect detectors, and on-board car detection systems, e.g., fire detection and alarm systems for passenger operations.

Indeed, there are overwhelming issues with the safety of TRR’s operations. The study that is being performed by my colleagues and I, will address those issues as well as identify advanced traffic management concepts that will support TRR’s increasing requirement to mix freight with passenger service on critical corridors. I know now that there are many railroads across the globe that could benefit greatly, both as to safety and financial viability, by having such a study performed without prejudice to particular approaches, equipment, or suppliers. Such a study would take into consideration safety systems, maintenance practices, personal accountability, and theft, as well as the peripheral safety considerations mentioned above.

Your correspondence is most welcomed and encouraged.

Teddy Bear- No Time For Strategy

Arguably, the most frequent Teddy Bear (i.e. fatuous, rationalizing statements) coveted and expressed by railroaders and suppliers alike is “We have no time for strategy. . . too much going on.” As a consultant that focuses on the strategic deployment of technologies aligned with the appropriate changes in the business processes (a.k.a. strategic railroading), I have been able to maintain my cool in such conversations by chiming in with “Really?”, and with some semblance of respect, I believe. But, what I want to do, really, is reach across the desk and slap the guy silly while calmly screaming “What in the world are you thinking here?” … or … “You need to let go of those next-year’s bonus issues for a moment.” … or … “So, I guess you don’t own, or plan to own, stock in the company?” Granted, I have a self-serving interest in getting this individual to think beyond the horizon of his bonus plan. And, if s/he did so we could have a win-win … Really!

Approaching a railroad or a supplier to talk about technology and process strategies, either individually or ideally together, is not a simple cold-call situation for which I was well trained 40 years ago during my span with IBM. Back then IBM was challenged with getting business executives to understand the value of computers to handle simplistic clerical efforts, e.g., updating inventory, accounts receivables, and processing payroll. Back then, the primary functions didn’t change with the use of the computer. The clerks just disappeared. Therefore, any business executive with a clerical workforce was a possible mark for a computer salesperson that could spin business cases. As such, a major part of IBM’s training was on how to make and present the business case using real-world adaptations to the principles that the thousands of MBA’s that were hired had learned in class. We talked about inventory turnover, return on investment, internal cost of capital, discounted cash flows, regression analysis, and even econometric modeling. BUT, we didn’t talk about changing the underlying business processes beyond that of the back office; we didn’t get into the functional operations of the company. The point here is that making a cold-call on an executive back in the 70’s was not the same as hitting on Operations management of today that don’t understand what technologies can do for their core business processes.

Today, there are four primary challenges to advance railroad operations in sync with a strategic technology plan.

The first challenge is identifying which positions in the individual railroads and across the supplier community would be willing to talk about technology and/or process strategy? Unfortunately, to my knowledge, there is not one position associated with operational (non IT) technologies in any of the railroads or the suppliers that have any form of the Greek root strategia in its title. Additionally, as I have pointed out in other postings on this blog, there aren’t even technologists. That is, while the railroads and suppliers have scores of technicians that push technologies at any costs, there aren’t those individuals that could do so in a pragmatic, cost-effective fashion, with or without modifying the underlying processes to take advantage of what the advancing technologies can do.

The second challenge is that the focus of the Class I railroads to meet the Positive Train Control (PTC) mandate deadline of 12/31/2015 has been the black hole of technicians. They have been totally and reluctantly drawn into the challenge of interoperability, or so it would seem. Actually, what has really happen is that they have willingly escaped into their respective caves to do what they really like to do; design the ultimate technology platform, whether or not it is required. No one is watching, challenging, or redirecting these guys because they are the High Priests of what can has to be done … and no one else really understands, and therefore challenges, the underlying principles of their religion.

The third challenge, therefore, is getting railroad operations management involved so as they will take charge of advancing their railroads via advancing technologies based upon sound business logic that is both pragmatic and cost-effective; business cases that include terms like return on investment, discounted cash flows, regression analysis, etc. Again, there is no position in the railroads currently that could be reasonably charged with this responsibility: It certainly isn’t the CIO. What is needed is a Chief Technologist or something like that … maybe Chief Strategic Technologist, whatever.

Lastly, the fourth challenge is that of involving and evolving the suppliers. With only one exception in the past 2 decades in North America, they have kowtowed to the tactical issues that drive their railroad customers so as to make their bonuses. The bottom-up approach to marketing products and services in the rail industry is a very traditional approach and rightfully so for the past 100 years because the technologies have been, aaahhh … traditional. Now, wireless data offer a paradigm shift in operations, just as IT has evolved over the past 40 years, and to bring the possible advancements to the industry will require top-down marketing. That simply isn’t happening today … and probably won’t until the PTC issue has subsided sometime after the < 2016 deadline.

The good news is that I am starting to hear rumblings from railroaders and suppliers alike that the PTC interoperability issues are out of control. Indeed, it is possible that perhaps some railroads won’t buy into the 220 MHz network as it being the universal wireless data panacea. Indeed, the requirement for a Communications Management Unit (CMU) on board to handle multiple wireless paths, as first addressed in my quarterly journal Full Spectrum a decade ago, is hopefully being revitalized. Maybe, it never really died in the minds of some, especially when the 220 MHz network began being slammed down the throats of several Class I’s two years ago.